Course Description

This is an advanced course on modeling, design, integration and best practices for use of machine elements such as bearings, springs, gears, cams and mechanisms. Modeling and analysis of these elements is based upon extensive application of physics, mathematics and core mechanical engineering principles (solid …

This is an advanced course on modeling, design, integration and best practices for use of machine elements such as bearings, springs, gears, cams and mechanisms. Modeling and analysis of these elements is based upon extensive application of physics, mathematics and core mechanical engineering principles (solid mechanics, fluid mechanics, manufacturing, estimation, computer simulation, etc.). These principles are reinforced via (1) hands-on laboratory experiences wherein students conduct experiments and disassemble machines and (2) a substantial design project wherein students model, design, fabricate and characterize a mechanical system that is relevant to a real world application. Students master the materials via problems sets that are directly related to, and coordinated with, the deliverables of their project. Student assessment is based upon mastery of the course materials and the student’s ability to synthesize, model and fabricate a mechanical device subject to engineering constraints (e.g. cost and time/schedule).

Course Info

Instructor

Departments

Learning Resource Types

assignment

Problem Sets

notes

Lecture Notes

group_work

Projects

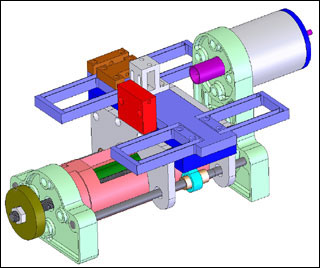

Students in this course design, construct, and analyze a high-precision desktop manual lathe. (Image by Martin Culpepper.)