| « Previous: student work sample | Next: Return to Assignment 5 description » |

By anonymous student

There is an inherent problem with the parametric frenzy of architecture: one cannot very well physically model the desired surfaces. It would be highly desirable to have a tool to physically visualize surfaces during development. In this project I was hoping to make a flexible fabric that can work as just such a tool.

“Structural Oscillations” by Gramazio & Kohler, Architecture and Digital Fabrication, ETH Zurich, in collaboration with Reto Geiser; Venice Bienalle XI, 2008. (Photo © Maris Mezulis. All rights reserved. This content is excluded from our Creative Commons license. For more information, see http://ocw.mit.edu/fairuse)

In order to create a malleable and posable fabric I set out to embed a metallic skeleton. I chose felt as a base material because it has a thickness that would allow for the embedment of the metallic grill necessary for the task.

Felt waffle embedded with wire grid = posable surface?

It was intended that the skeleton would be hidden within the felt grid creating a final posable felt surface. Little did I know the difficulties these materials would actually pose.

Process

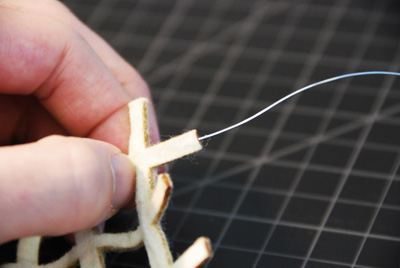

The felt was laser cut from an illustrator file and washed to remove the putrid smell. Even though the felt was 100% wool, it smells like burning wet dog hair after being cut. I used 24 gauge steel wire to create the skeleton. eighteen strands of wire were hand sharpened and each used as gigantic needles.

Running wire through the felt.

The process of piercing and running the skeleton required around 6 (!) hours of intense finger labor. However, it was discovered that by soaking the felt in hot water the metal was easier to run through. Keeping the wire contained within the felt was actually the hardest part.

Results

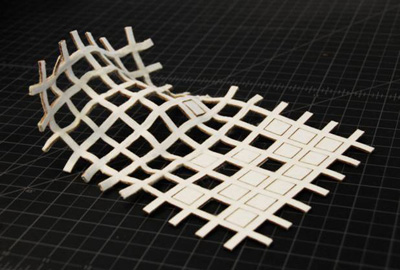

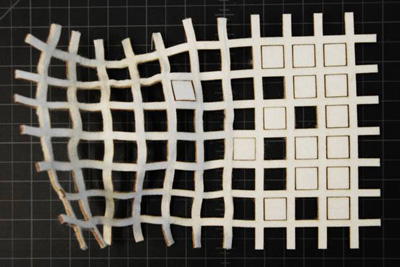

Due to the physical difficulty of constructing the posable surface and the expense of felt, a smaller proof of concept was created here. In the future it would be interesting to attach sensors to the grid intersection points. This would allow surfaces developed to be mapped and further sculpted digitally.

Posable surface – proof of concept (perspective view).

Another interesting possibility would be to use nitinol and make the form electrically dynamic. Perhaps for this purpose it would be better to make the skeleton one object and use two pieces of felt. Then it would be easy to sew the nitinol into a sandwich between the felt.

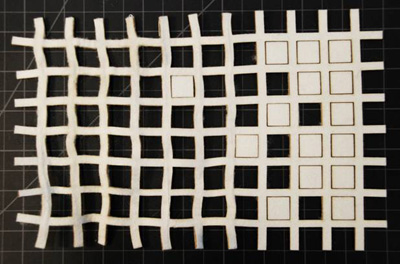

Posable surface – proof of concept (top view)

Posable surface – proof of concept (top view).

Conclusion

There is promise in the use of posable textiles in the development of complex mathematical surfaces. However, I think there are better ways to do it then using felt. Perhaps casting a steel wire skeleton in silicon would have been more expedient and possibly more usable in the end. But my quest to discover new uses of felt emerges somewhat victorious none the less!

| « Previous: student work sample | Next: Return to Assignment 5 description » |